SURFACE PLAN™

Reinventing the Wheel

for the 21st Century

Explore SurfacePlan™

on Wefunder:

WeFunder™ allows investments of as little as $100

An intelligent, actuated wheel that delivers direct thrust at the road.

By dynamically forming propulsion at the contact patch, SurfacePlan replaces centralized torque transmission systems: removing driveshafts, differentials, and complex gear assemblies from conventional vehicle architecture. Propulsion shifts from the center of the vehicle to the surface interface itself, enabling radically simplified structures that can be lighter, more aerodynamic, and mechanically efficient.

2/13/2025 - FAQ Section Updated

11/15/2025 - New Use Case Section Updated

2/12/2026 - National Law Review

2/15/2026 - Looking for compact, high-force actuators that can drive the future of mobility.

The Problem

Traditional drivetrains waste energy pushing power through pistons, shafts, gears, and axles before it finally reaches the tires. That means more weight, more parts, and more loss

EVs improved efficiency, but still rely on indirect power transfer and heavy architecture.

The Solution

The Intelligent Wheel embeds precision actuators at the tire surface, applying thrust exactly where it’s needed — directly into the road.

• Cut energy use by removing inefficient linkages

• Dramatically lighter vehicles; wheels-up design

• Single-person, linkable pods become practical

• Repairs may be as simple as a wheel swap

• Programmable tread & traction on demand

As a solo inventor, I’m seeking the right industry partner to bring this breakthrough technology to market - the goal is implementation, not ego.

7 Provisional patents filed. Complete filing planned within one year.

Count down to first filing

Time Remaining Below:

Exploring partnerships with proven industry leaders

How It Works (The Pin-Art Analogy)

Think of the classic “pin art” desk toy: many small pins moving independently to form a shape. Now imagine those pins as actuators at the tire surface, each delivering a brief, tangential push that propels the vehicle forward with minimal slip.

Direct thrust at the contact patch, smooth everywhere else for efficiency.

Where it Fits

• Automotive

• Electric Vehicles (EVs)

• Motorcycles

• Bicycles & E-bikes

• Off-road Vehicles

• Robotics

Why It's Different

• Direct-to-surface thrust reduces conversion losses

• Lower mass enables new vehicle forms (individual pods)

• Software defined motion & programable tread

• Manufacturing shifts to modular wheel units

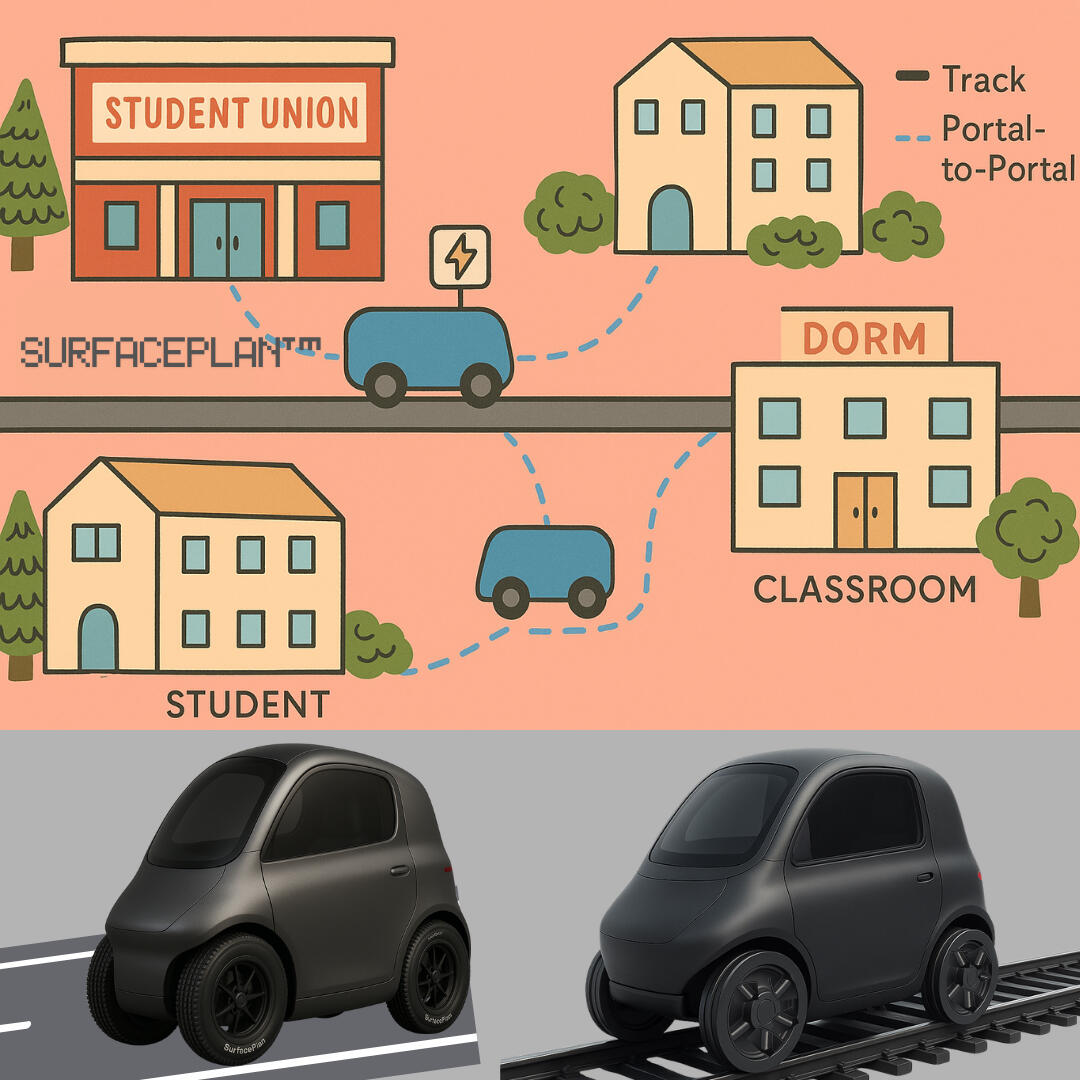

Travel Solo or in Families

Linking Pods: Flexible Travel, Shared Space

Traditional cars are built to move four or more people at once which means hauling extra weight and space even when you’re alone. SurfacePlan architecture changes that. Each pod is designed for one person, cutting vehicle weight dramatically and improving energy efficiency. Remember, the wheels are now the engine.When two, four, or more people want to travel together, pods can link side-by-side. In linked mode, cockpits align and doors slide away, creating a shared interior space much like a traditional car cabin while still allowing each pod to detach instantly for solo travel.This is mobility reimagined: light, efficient, personal with the option to connect.

Beyond Efficiency: A Complete System Transformation

The implications extend far beyond improved drivetrains. By eliminating engines, transmissions, drive shafts, and the heavy structural frameworks required to support them, while enabling lightweight single-person pod architectures, the system could achieve 60-80% weight reductions compared to traditional vehicles. A typical 3,500-pound car becomes a 700-pound personal transport pod. Since energy requirements scale with mass, this dramatic weight reduction - combined with direct thrust application and elimination of drivetrain conversion losses - could deliver order-of-magnitude improvements in energy efficiency rather than incremental gains.

Looking for the Right Partner

I’m open to equity, licensing or joint venture structures to help make this vision a reality. Possibly build a prototype within the provisional patent window.• Automakers seeking efficiency & control breakthroughs.• Tech companies ready for a design leap.• Universities with advanced transportation/ME programs• Venture investors backing transformative hardware.

Need Another Reason

• Dynamic road surface stability as programmable actuators adapt instantly to ice, gravel, mud, or uneven terrain, maintaining grip where rubber tires fail.

• Actuators are the pixels of motion. Instead of drawing light on a screen, they draw force directly into the road.

FAQ - Franco Asks Questions

Really: frequently asked questions - "Franco" is a smart guy and likes to challenge our thinking

Q: Won’t the actuators just push up and down, causing bumping instead of forward motion?A: No. Like a pneumatic tire, the actuator tips and surface skin are designed to deform at the contact patch, converting force into tangential thrust. Sequencing them in traveling waves creates smooth propulsion - think more inchworm glide than jackhammer.Q: Isn’t this just a wheel hub motor?A: Hub motors apply torque at the hub, turning the whole wheel. SurfacePlan eliminates torque transfer entirely by generating propulsion directly at the road contact patch. Instead of one big motor, each wheel has multiple distributed actuators that are programmable, redundant, and efficient.Q: How does SurfacePlan affect vehicle aerodynamics?A: SurfacePlan shifts propulsion from centralized drivetrains to the wheel interface itself. By eliminating transmission tunnels, driveshafts, and bulky mechanical assemblies, vehicle architecture can be reconfigured around aerodynamic efficiency rather than drivetrain packaging constraints. While final drag characteristics depend on full vehicle design, decentralized propulsion enables lower profiles, cleaner underbodies, and reduced frontal area compared to conventional layouts.Q: Won’t multiple inverters and cables make this too complex and expensive?A: A hub motor concentrates all power into one heavy unit that needs thick cabling and a high-capacity inverter. SurfacePlan spreads the work across many light actuators, so each needs only a small pulse of power. That means lighter wiring, simpler electronics, and a common power bus instead of dozens of separate inverters. The control brain is lightweight and directs timing, not heavy current, the opposite of “complex and expensive.”Q: How is traction managed on ice, gravel, or mud?A: Each actuator is like a pixel of motion. Instead of a fixed tread, SurfacePlan can reprogram its traction profile in real time thus optimizing grip per surface, something no passive tire can do.Q: Isn’t a tire already good enough at traction?A: A tire is one big, molded object. Its tread is always passive, and every rotation it meets the road the same way. Even clever tread designs or dual-compound tricks are still passive. SurfacePlan is active: each actuator is its own mini motor, programmable in real time. That gives variability in how the wheel handles terrain and road surfaces - something no molded tread can match.Q: What about unsprung weight and ride quality?A: In today’s cars, “unsprung weight” is defined relative to a heavy drivetrain sitting on top of the suspension. With SurfacePlan, vehicles will get lighter because the engine and drivetrain disappear. That changes the balance entirely. And unlike a rigid hub motor, our actuators themselves can provide compliance absorbing some shock naturally.Q: What’s actually being suspended - the whole car?A: In conventional vehicles, the suspension has to carry the engine, transmission, driveline, passengers, cargo, and batteries. With SurfacePlan, the heavy driveline disappears. The only things that really need suspension are the passenger, payload, and a reduced battery bank. Each wheel’s actuators act like mini shock absorbers at the contact patch, and elbow-type joints (part of our patent) provide steering and added suspension control.Q: What about ride comfort?A: Today’s suspension systems react after the bump. SurfacePlan wheels can eventually act as active suspension, softening impact at the contact patch or even predicting and canceling it before it happens. That’s comfort built in at the wheel.Q: What about durability, dirt, potholes, and wear?A: Durability is an engineering and materials challenge, not a show-stopper. The actuator tips carry a stretchable outer skirt that moves with them, shielding the mechanism from grit and debris. Wear parts are modular and replaceable (more like brake pads than tires). Short strokes and sealed paths limit intrusion, and because the whole vehicle is lighter, impact forces are far lower than on today’s cars.Q: Won’t the actuators just get caked with mud like normal tires?A: Mud is a huge challenge even for today’s best off-road tires as they fill up, smooth out, and stop working. SurfacePlan is different: the “tread” isn’t fixed. Each actuator can flex and fire to shed mud on demand. That means the wheel can actively clear itself instead of waiting for rotation and centrifugal force to maybe fling debris out.Q: What if one actuator jams? Won’t that cause failure?A: Redundancy is built in. A wheel contains multiple actuators, and the control system simply routes around a fault. One stuck actuator doesn’t disable the wheel - it gets isolated and scheduled for maintenance.Q: Does it coast, or is every stroke wasting energy?A: Current pneumatic tires rely on constant air deformation, which wastes energy as heat. SurfacePlan actuators can lock in place, letting the wheel coast without kneading a big rubber carcass. Efficiency must be measured at the system level: one wheel replaces the motor, gearbox, driveshaft, differential, much of the braking, and some suspension; a cascade of weight and energy savings.Q: What about heat dissipation?A: Heat is actually easier to manage in SurfacePlan wheels than in a single big motor. Each actuator produces only a tiny pulse of energy, spread across the entire circumference. That distributes heat over a large surface area right at the tire edge, where airflow naturally cools. Instead of finding ways to vent a large, buried motor, heat is managed passively and evenly.

Welcome, Rail Research Week Attendees

(Nov 18–21, 2025 · The Broadmoor, Colorado Springs)

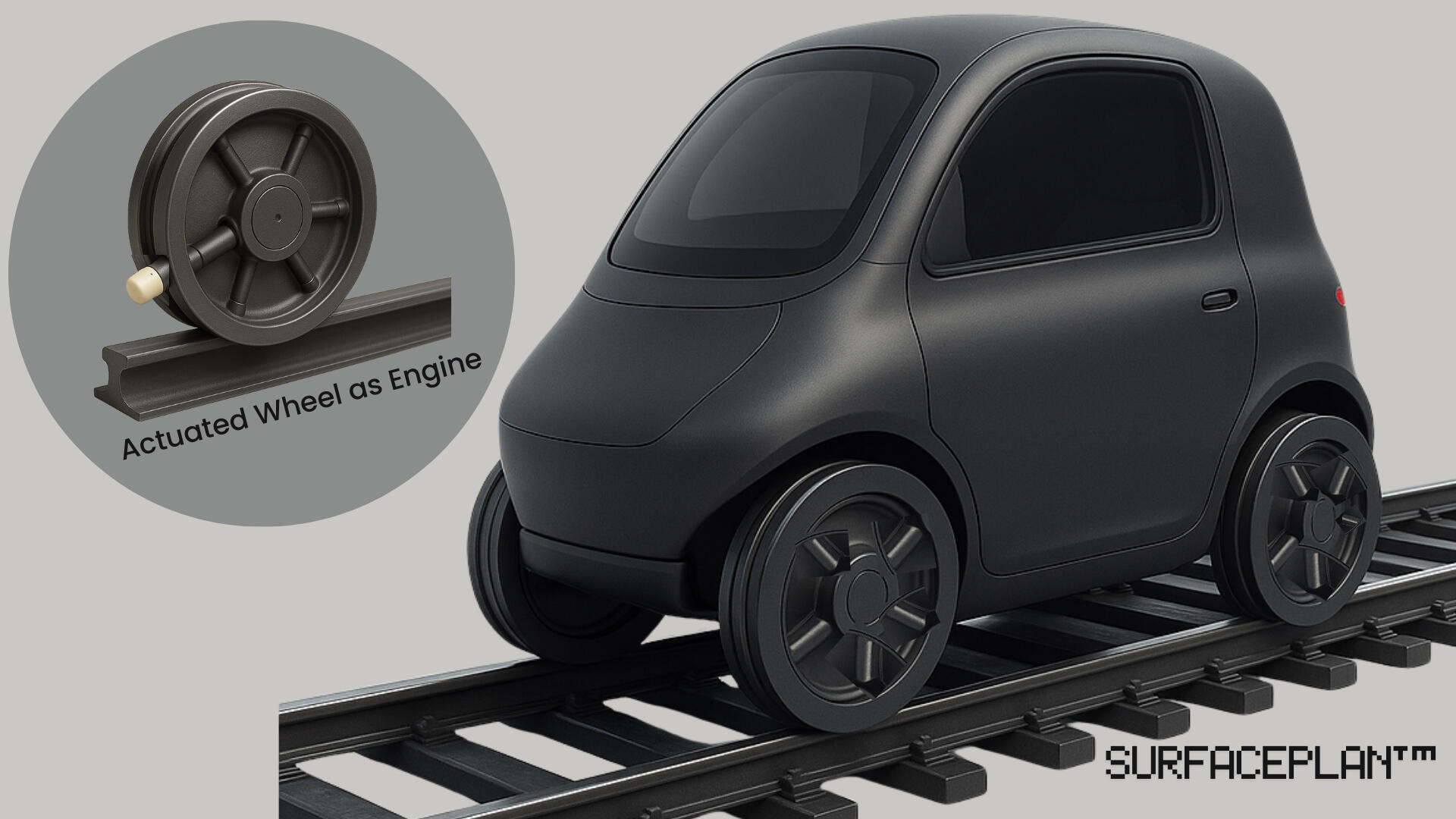

Use Case Inspired by Our Community - UltraLight Light Rail

If you’re attending Rail Research Week at The Broadmoor, you can sign up here:

To get access to ongoing technical advancements in SurfacePlan’s on-rail / off-rail ultra-light rail wheel system.

Inventor’s NoteWhen I first designed the SurfacePlan wheel, I imagined many potential uses. But light rail wasn’t on my radar, and while I considered EVs, I didn’t recognize the unique charging advantages the SurfacePlan design offers.Both of these possibilities were pointed out almost immediately by the engineering community. And they may be right: combining ultra-light rail with the SurfacePlan wheel could be the first best use of this innovation. It makes a ton of sense because SurfacePlan starts with a new kind of wheel, one not tied to pneumatics, but to direct actuators. That makes the system far more flexible: it can be designed for both off-rail mobility and ultra-light rail efficiency.On rail, the advantages are dramatic. Rails provide a smooth, consistent environment - the perfect proving ground for actuated propulsion. Energy use drops to a fraction of conventional vehicles, because there’s no heavy drivetrain and rolling resistance is extremely low. Even shallow guide inserts in existing streets can deliver rail-like performance at a fraction of the cost and disruption of traditional light rail.Off rail, the same pod is still effective. Actuators handle steering with the help of AI, keeping vehicles stable and nimble. That makes SurfacePlan practical for the “last mile,” it can leave the guideway to reach neighborhoods, campuses, or door-to-door destinations. Charging pads can even be built into guided on-ramps, so vehicles gain meaningful range while waiting to enter highways.In short: ultra-light rails deliver unmatched efficiency, off-rail operation delivers flexibility, and together they unlock a transportation system that’s both practical and transformative.

9/26/2025 Email from community *** "Use idea: Connected cars to form trains running along a uniform track surface allows for the wheels of all cars in the train to use piston push. Each car can be equipped with a small power source for synchronized operation of all pistons on all cars. Might initially try this on a new city light rail being developed.~from Bill9/26/2025 Email from community "Use idea: Wanted to toss this your way, do with it as you will - it's yours if it's useful to you: your tech could have cool possibilities for inductive and non-inductive vehicle charging. Build it in. Been doing some work on optimized transport networks and that struck me on reading your plan..~from Michael

Incredibly efficient on tracks and able to cover the last short distance over ground for true portal-to-portal mobility

Pod designs are customizable for many special requirements because the wheels are the engines. And with actuators at ground level, charging is built in and ideal

UltraLight Light Rail - The SurfacePlan™ Vision

• SurfacePlan starts with one breakthrough idea: the wheel itself is the engine - not as a bulky hub motor, but through lightweight actuators at the ground surface. From this design, an entirely new kind of lightweight, flexible transportation system becomes possible. • UltraLight Rails: Because propulsion happens in the wheels, pods don’t need heavy engines or drive systems. The track can be lighter and cheaper, even simple concrete rails. • Portal-to-Portal: Pods can run efficiently on rail, then drive off-track to reach final destinations creating seamless door-to-door transport. • Integrated Charging Made Simple: Unlike rubber tires, SurfacePlan wheels have actuators at ground level. That makes them perfect for direct contact with embedded charging pads or coils in the rail. Energy flows right where the wheel touches, without extra connectors. Pods can charge while waiting or moving, which means smaller onboard batteries are possible. • Radical Body Designs: With no heavy drivetrain to design around, pods can be built for specific needs from wheelchair-accessible rear-entry pods to cargo carriers or other specialized uses. • Scalable & Flexible: Pods can operate independently or link together as a train, adapting to demand without needing traditional engines.

SurfacePlan™ - A project in development in Pagosa Springs Colorado

Contact: use form on this page or:

500 Westover Drive, Ste 15985

Sanford, NC 27330 USA

© 2025 SurfacePlan™. All rights reserved. Patents Pending

SURFACE PLAN™ PRESS & MEDIA COVERAGE

Feb 12, 2026: Transportation Infrastructure May Add 200 Billion Tons of Excess Weight to Civilization

Jan 6, 2026: Reinventing the Wheel Means Reinventing Terminology

Nov 19, 2025: Colorado Inventor Promotes New Hybrid Ultra Light Rail Wheel Concept During Rail Research Week

Oct 20, 2025: AI Analysis Projects 100-Million-Part Demand for Actuated Wheel Technology

Oct 16, 2025: SurfacePlan réinvente la roue avec un dispositif qui exerce une poussée sur la route

Oct 7, 2025: Investors Drawn to Reinventing The Wheel: SurfacePlan™

Sept 30, 2025: 2,000 Engineers Worldwide Examine the Wheel of the Future

Sept 25, 2025: INTELLIGENT WHEELS:

Rad soll Automotoren ersetzen

Sept 23, 2025: Direct-push wheel design would replace the whole drivetrain

Sept 19, 2025: Inventor David Henson Aims to Put Cars on a Weight Loss Plan by Making the Wheel the Engine

Sept 18, 2025: Traditional Pin Art Toy Inspires Wheel-as-Engine EV Technology, Now Under Investor Review

SurfacePlan™ - A project in development in Pagosa Springs Colorado

Contact: use form on this page or:

500 Westover Drive, Ste 15985

Sanford, NC 27330 USA

© 2025 SurfacePlan™. All rights reserved. Patents Pending

**SURFACE PLAN™ REQUEST FOR PROPOSALS

Oct 15, 2025: Request for Proposals: High-Cycle Linear Actuators for Actuated Wheel Prototype (SurfacePlan™)

We are scouting actuator options for an early prototype of our SurfacePlan™ actuated wheel, a propulsion concept where linear actuators embedded inside the wheel directly drive wheel motion.

The project has already received positive media attention for its engineering ambition. While this is an early-stage and technically challenging development, success could ultimately require hundreds of millions of actuators for scalable transportation applications.

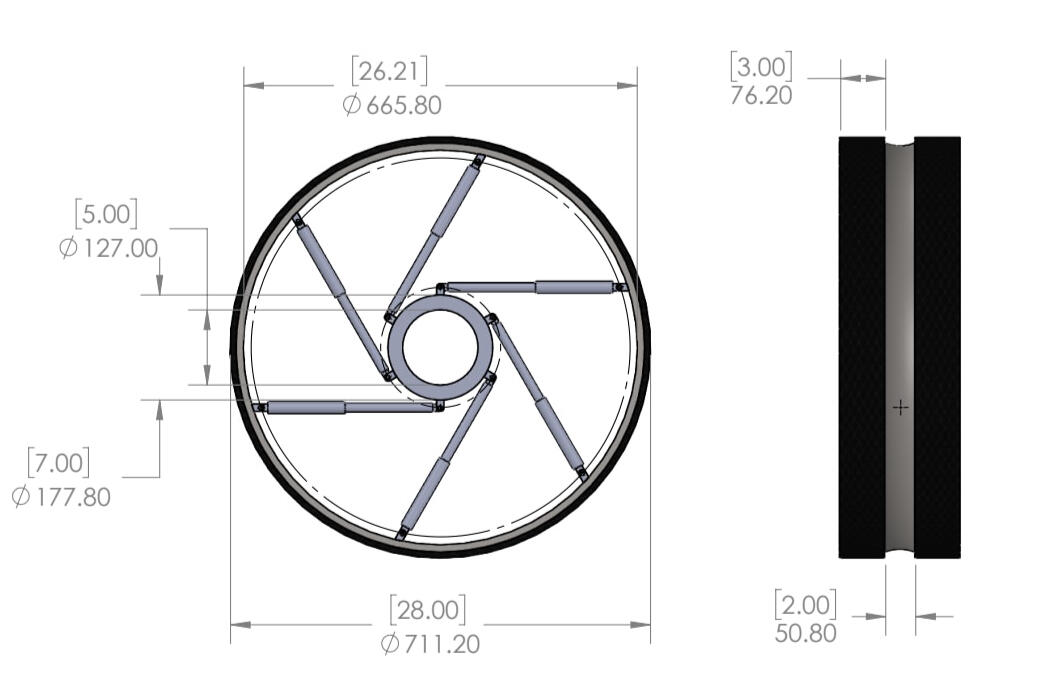

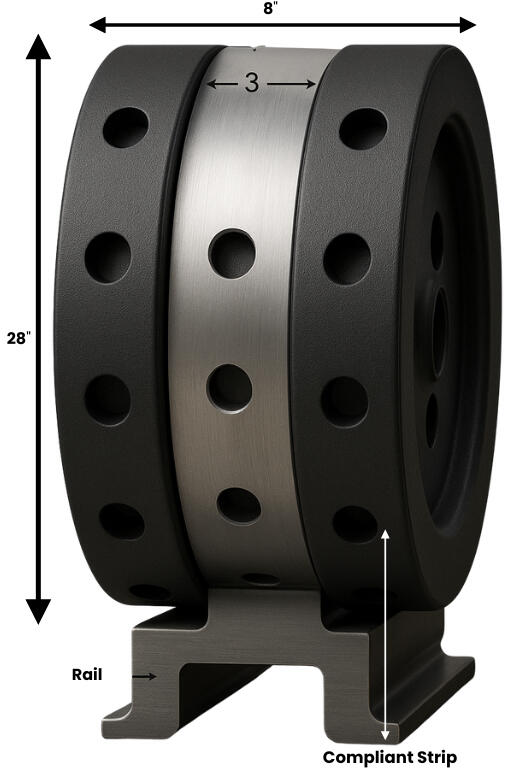

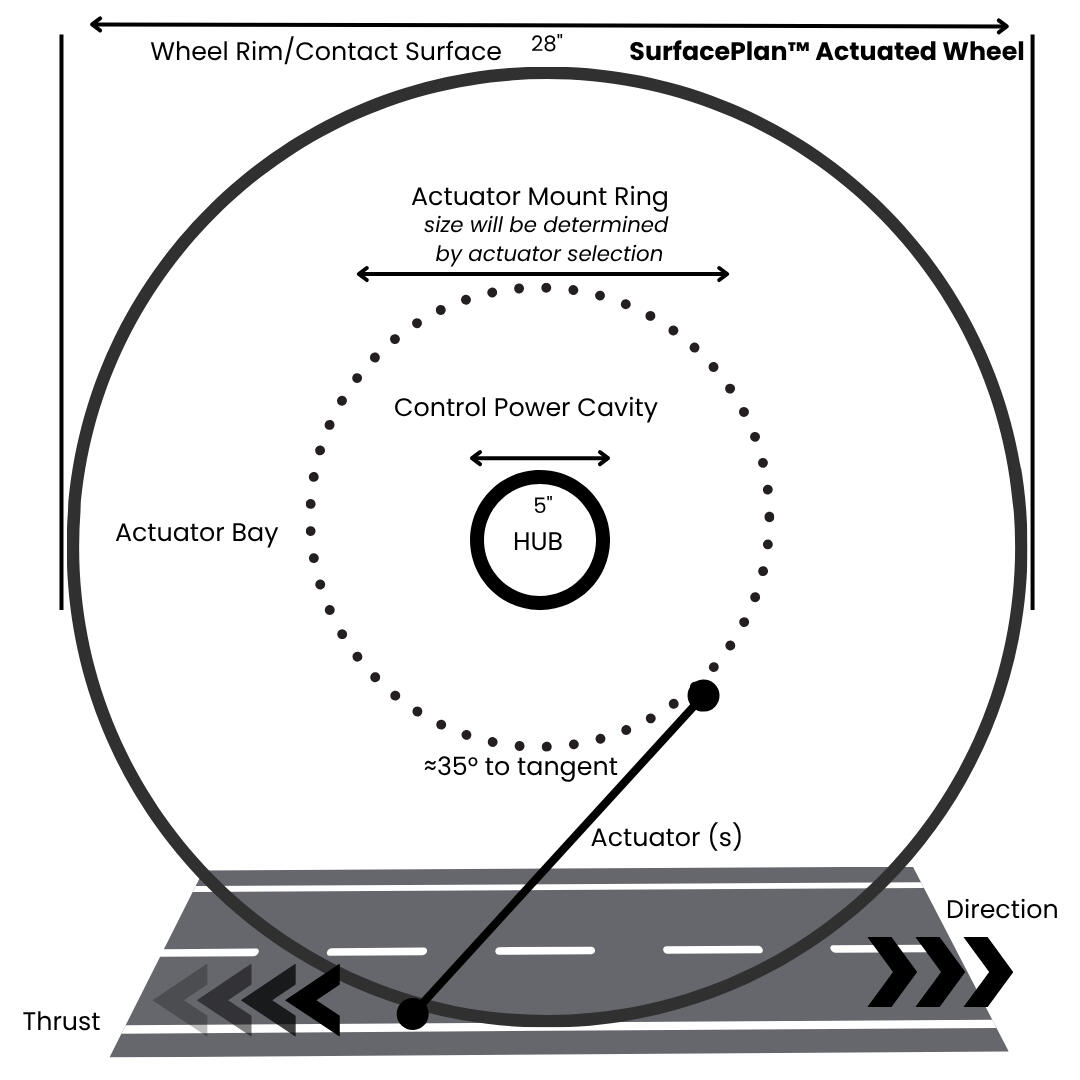

The goal is to move a 1,600-lb (≈727 kg) pod that operates both on a ultra-light rail and off-rail road surfaces. The actuators push directly against the rail or road surface via deformable tip at contact patch and generate forward motion.Basic parameters:

• Wheel size: 28 in Ø × 8 in W

• Actuators per wheel: ~18 total, typically 8–12 active across four wheels at any time (this number will vary based on actuator size and technology)

• Stroke: 20–30 mm preferred (software-limited initially)

• Force: ~200–400 N peak (please include continuous/sustained force)

• Vector: ~35° to the wheel tangent

• Duty: high-cycle, high-frequency motion

• Environment: sealed wheel cavity, moderate heat buildup expectedThermal & Duty:

We recognize that heat buildup and duty-cycle limits are key design considerations and would appreciate your input on how your actuators manage thermal performance in continuous or high-frequency applications.Electrical:

We expect electrically powered linear actuators (voice-coil or equivalent) that can operate from a shared DC power distributor.

Attached are two concept renderings and a technical schematic illustrating the intended geometry and actuator mounting concept. These are conceptual and meant only to communicate design direction and performance goals.We would welcome any candidate actuator recommendations, datasheets, or sample unit suggestions that could meet or approximate these needs.

Looking for the Right Actuator

Have the right actuator- or know who does? We’re looking for partners who can help bring the SurfacePlan™ actuated wheel to life.Share your actuator, your lead, or your idea using this form.With four provisional patents filed, we’re seeking voice coil actuators (or equivalent linear technologies) for our Q2 2026 prototype.NDAs are available upon request to protect your technology and ours.Or reach out directly: David (at) SurfacePlan.com